From waste to wealth, circular economic models go beyond the ‘take-make-dispose’ principle to ensure more sustainable supply chains and products that have a second life.

The traditional economy is built on the idea of “take, make, dispose”. It’s linear, economically inefficient and unsustainable. But in a circular economy, companies look to take end-of-life products and push them back into the economy as a resource.

It’s a circular economic model that aims to keep resources in use for as long as possible, to extract the maximum value from them while in use, and to recover and regenerate products and materials at the end of their service life.

“So you’re continually using these resources and not using the planet’s finite resources,” explains Kirstie McIntyre, Global Director for HP Inc.’s social and environmental responsibility operations.

McIntyre is also a founding member of the Ellen MacArthur Foundation, a global organization focused on promoting the concept of a circular economy.

Loading...

READ MORE | #30Under30: Technology Category 2019

“There are some big challenges in sustainability. There are challenges now, and they will be more acute in the future,” McIntyre says. “It also means companies need to question and innovate in fundamental ways. This isn’t just about a little bit of recycling.”

Circular economy theory questions how we can maintain a thriving economy within the limits of the planet, taking both resource depletion and climate change into account.

“When you work in sustainability, it can be quite depressing. There are plenty of smart people doing space exploration; Elon Musk is one of them. But I don’t think we can afford to wait for Elon Musk to find another planet for us to pull resources from, I think we’ve got to get on with this now, ourselves,” adds McIntyre.

HP’s framework revolves around doing more with less. It’s about moving away from simply recycling and into a functional circular economy. And it’s more than eco-printing for a “forest-friendly” future where more trees are planted than are cut down to enable printing operations.

“There are big sustainability issues in front of us. We have a large responsibility because we’re leaders in our industry. It’s about ensuring our products, where possible, have a second life. When that’s not possible, they’re taken apart so we can use the components,” says McIntyre.

Innovations that matter are innovations that have a positive impact. HP is just one of many companies working towards the idea of a circular economy; in 2018, trans-national consumer goods company Unilever revealed that its sustainable brands grew 46% faster than the rest of the business, delivering 70% of its sales growth.

Caroline Laurie is the Head of Sustainability at Kingfisher. In a digital-first world where transparency and provenance are becoming increasingly prevalent, Laurie believes that businesses can actually benefit from becoming more sustainable.

“Sustainability drives you to think differently about your business. Customers’ expectations of big business are getting higher, yet their trust in big business is getting lower. You’ll very rarely find consumers making a choice between two products. But what they want to know is that you’ve made that choice for them. It is often about range editing. Customers want to trust in brands to do the right thing,” explains Laurie.

In other words, sustainability done right brings consumer trust, and with it business, commercial, social, and environmental benefits.

“None of us can solve these issues on our own in isolation. This is about complete value chain re-engineering. This isn’t about philanthropy anymore, it’s about real commercial sense,” ends Laurie.

The war on plastic straws

Coffee shops are turning to glass and paper as alternative sipping options, with some restaurants even offering tubes of pasta as an alternative, more sustainable solution to the traditional plastic drinking straw. There’s a war on plastic straws, and it is the start of both companies and consumers becoming more conscious of the use, reuse, recyclability and disposal of plastics… but is our focus wrong?

“Customers rarely understand the relative environmental impact of different types of materials,” says Andrew Smith, the CEO and co-founder of Yuppiechef, the kitchen-focused e-commerce website.

“They believe plastic is bad and paper is good, but this is not always true. Plastic is often recyclable and can have very little environmental impact.”

Moving away from single-use plastic – and applying the principles of the circular economy – the New Plastics Economy initiative was formed towards the end of 2018 with the over-arching goal that plastics never become waste. The organization believes that instead they should re-enter the economy as part of products made from recycled plastic material wherever possible.

Digital twins?

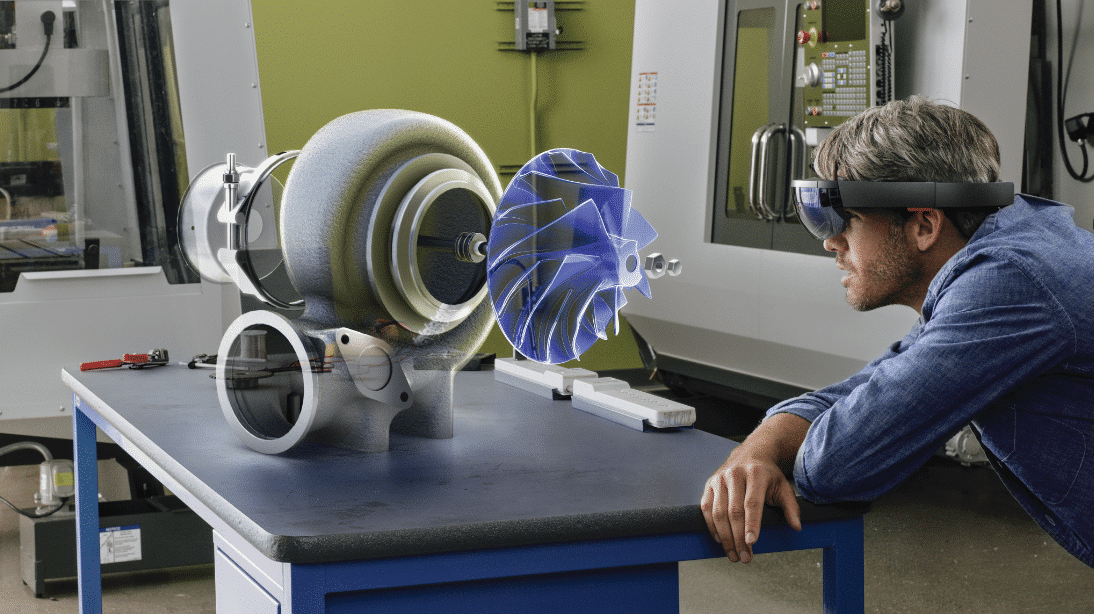

Technology has a massive role to play in creating a greener supply chain. For many, this means the use of artificial intelligence (AI), virtual reality (VR), and digital twins. A ‘digital twin’ is a 1:1 digital copy of a product, process or service, used to provide deep technical training on a device or service without requiring a physical representation of said device or service. According to research and advisory company Gartner, 50% of large industrial companies will use digital twins by 2021.

Jason Ried is the Founder and Managing Director of Fuzzy Logic, an innovative software development company based in South Africa’s Western Cape province that has created digital twins of large machinery for mines and automotive and healthcare companies.

READ MORE | Forbes Africa #30Under30 list: Business, Technology, Creatives and Sport

“Using augmented reality solutions on mobile devices or headsets (like Microsoft HoloLens), we allow users to ‘see’ a digital representation of the machinery they’re being trained on as if it was really there,” explains Ried.

“Users can get a sense of the scale and design without needing the real thing in front of them. They are able to assemble and disassemble the machine as many times as required to fully learn its intricacies, while each action is digitally tracked and stored, allowing management to understand how well each user performed.”

From a sustainability point of view, there are major benefits in the creation and use of ‘digital twins’ in business: not only do digital twins save time and money, they enhance learning by increasing the quality of training and retained knowledge.

Once digital twins are integrated into business workflows, companies like Fuzzy Logic can further enhance productivity by overlaying digital data onto physical objects.

“Users might, for instance, see steps to repair a part, while info like current temperature and pressure display alongside the machine, updating in real time as users interact with it. This strengthens the link between digital and physical objects,” he says.

Ultimately, the concept of a circular economy is about doing more, with less. Gartner’s Managing Vice President, Steven Steutermann, says it best:

“The goal is to deliver customer value with minimal waste,” Steutermann says. “For such a system to be efficient, it must be automated, and this is where the previous factors come into play. Using technologies such as digital twins and AI in an automated fashion enables the supply chain to execute against circular economy principles by acting on its own and ultimately becoming its own ecosystem.”

-Tiana Cline

Loading...